Past Work: Contiguous Capillary Coating to Form Silicon Sheets

| This

multicrystalline Si ribbon growth process was originated in the late

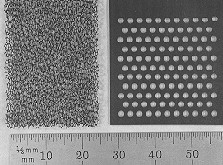

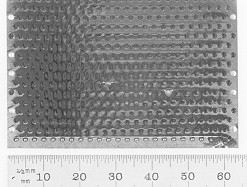

1970's1,2. In this method, a porous or grid-like sheet of carbon

is passed through a Si melt to form a crystalline-Si coating that is contiguous

from the rear surface to the front surface. Because the substrate carries the

liquid coating along with it, very high speeds can be attained, with solidification taking place

some distance out of the melt reservoir where thermal profiles for heat removal can be

tailored. An example of a reticulated vitreous carbon substrate and a machined

graphite substrate are shown below, along with a Si-coated substrate. This

technique was later developed further at Seimens AEG in Munich, Germany, and

retitled the s-web method. |

|

|

______________________

1. T.F. Ciszek and G.H. Schwuttke,

"Inexpensive Silicon Sheets for Solar Cells," NASA Tech. Briefs,

Winter (1977) 432.

2. T.F.

Ciszek and J.L. Hurd, "Contiguous Capillary Coating of Silicon on Porous Carbon

Substrates," in: l4th IEEE Photovoltaic Specialist Conf.

Record, San Diego,

Calif. Jan. 7-l0, 1980, IEEE, New York, l980, pp. 397-399).

|